Complete Patent Searching Database and Patent Data Analytics Services. The casing and the treadbelt assembly.

Tire Manufacturing Process Youtube

The green tyre will pass through the process of Vulcanization along with the application of pressure and heat in special machines in order to produce the final and finished product that is tyre.

Green tyre building process. Heat and pressure are applied to the tire for the prescribed cure time to yield a resilient and durable finished tire. The belt systems main function is to provide stability to the tires tread area which contributes to wear handling and traction. Curing bonds all the different rubber components of a tire together and also molds the tread design and sidewall nomenclature into the tire.

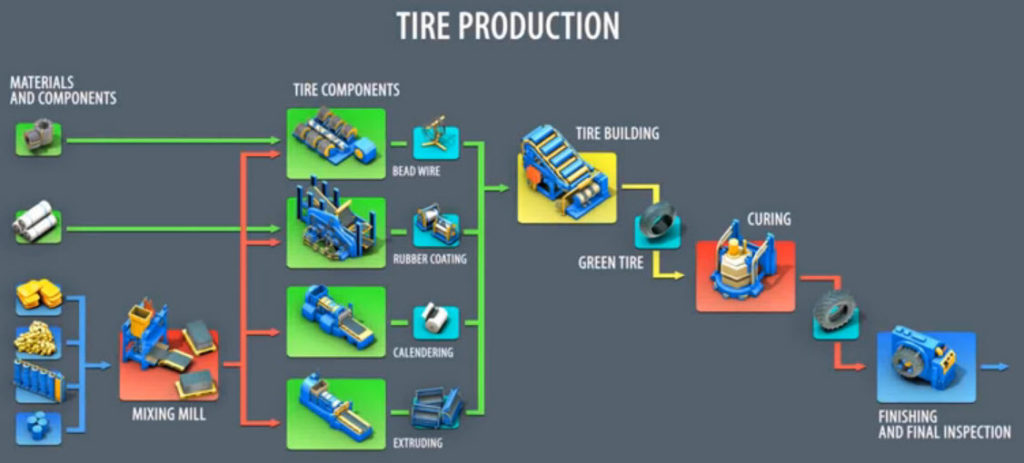

Now the tire building can begin. The latex is collected in a vessel and it is allowed to coagulate which givesyou the solid rubber which can be further processed in to sheets. The various semi-finished products come together on the tire building machine and are assembled into what is known as a green tire This is done in two stages.

Through the manufacturing process from once a bulky waste a secondary raw material is obtained. Vulcanize is the one of the process of tyre manufacturing. Rubber granulate and rubber powder 0 4 mm ASTM E 11 o DIN ISO 3310 free of steel and fibers at 99.

When the components have been drawn onto the belt drum of an assembly machine and the frame of a tyre has been set on the bulkheads of the stretching machine the machines loading wheel transfers the unity formed by the surface and the belt onto the frame. Cimcorp Dream Factory creates an optimal buffer of green tires between the building machines and the curing presses optimizing material flow into the presses and eliminating. Process for building different types of green tyres for vehicle wheels for each tyre size through the use of elementary semi-finished products in a building plant comprising a plurality of work stations the process comprising.

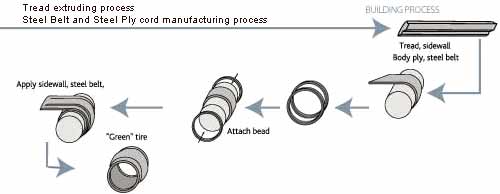

A building a carcass structure of a green tyre said carcass structure comprising at least one carcass ply and a pair of annular anchoring structures. This process begins with the green tire being placed into a press which contains the mold for the tire. EP2387500B1 EP088757802A EP08875780A EP2387500B1 EP 2387500 B1 EP2387500 B1 EP 2387500B1 EP 08875780 A EP08875780 A EP 08875780A EP 2387500 B1 EP2387500 B1 EP 2387500B1 Authority EP European Patent Office.

Find your Yokohama Tires. Components assemble and build-up phase. Furthermore in the tyre building process different parts of tyres are fixed with the help of high-tech technology it is a raw tyre which is also called green tyre.

This green tyre is then automatically placed into high-tech multi-segmented moulds for curing from where it comes out as a newly manufactured tyre. The coagulation process canbe controlled by chemicals like Ammonia Formic acid. A building a carcass structure Ia of a green tyre on a forming drum said carcass structure Ia comprising at least one carcass ply 3 and a pair of annular anchoring structures 5 said at least one carcass ply 3 being built by laying circumferentially contiguous strip-like elements.

When the press closes the green tire is pressed into the mold forming the sidewall and tread design. Compounding and Banbury mixing. DARB 4500 Intralox Dual-Stacked Angled Roller Belt DARB S4500 technology is the ideal touchless solution for high-rate sorting merging and diverting of green or finished tires both passenger and truck.

The belts nonstick nonporous material prevents green tires from adhering creating fewer mistracks and allowing the belt to be used as a buffer zone. Tyre makers assemble the components into green tyres using assembly machinery. Process and plant for building green tyres for vehicle wheels Download PDF Info Publication number EP2387500B1.

There is described a process for building a green tyre 1 for vehicle wheels comprising the steps of. Ammonia decelerates the coagulationprocess whereas Formic acid accelerates it. In the first stage the rubber patterns like tread bead are mixed together in the TBM Tyre building machines.

Tire components are assembled like a puzzle and molded together in the curing process which causes the tire components and rubber compounds to adhere to their surrounding components to create a singular product. As the throughput of the curing presses determines the ultimate production capacity of the tire plant keeping the presses curing is paramount. The green tire is transformed into a final product during the curing vulcanization process.

The process that forms the green tire into the desired shape and size under heat and pressure. Processing 15000 tons car and truck tyres per annum Green Tyre Project employs the latest best equipment on the market. This green tire is then sprayed with.

Pics Apollo Tyres Chennai Factory Detailed Report On The Making Of A Tyre Team Bhp

Tire Manufacturing Process Pneumatics

Shyr Chiuann Machinery Industry Co Ltd

Pics Apollo Tyres Chennai Factory Detailed Report On The Making Of A Tyre Team Bhp

Manufacturing Process Products Aircraft Tires Bridgestone Corporation

Process Flowchart For Manufacturing Green Tire Download Scientific Diagram

Using Pressure Switches In Tire Curing Manufacturing Ccsdualsnap

Tire Manufacturers Increase Efficiency With Precision Machine Alignment

Manufacturing Process Products Aircraft Tires Bridgestone Corporation

Manufacturing Process Products Aircraft Tires Bridgestone Corporation

Tyre Manufacturing Fleet Solution Bridgestone Your Journey Our Passion

Process Flowchart For Manufacturing Green Tire Download Scientific Diagram

A Journey Of The Rubber That Transforms Into A Tyre Deccan Herald

Manufacturing Of Tyres Tubes And Flaps Salsons Impex Pvt Ltd

Komentar

Posting Komentar